The Power Deck blasting technique was introduced in open pit blasting in 2001 by the Power Deck company. This explosive technique, in addition to improving the results of the explosion, also reduces its adverse effects. The basis of this system is the creation of an empty space by water or air at the end of the pit, for which the term air charge is suggested.

In this explosive method, additional drilling in explosive blocks is reduced and even eliminated, and according to the diameter of the hole and the height of the step, a certain area of the bottom of the hole is left empty, and after pouring a certain amount of drilling fragments, the costing is done under the usual conditions. takes

In this method, the air column in the lower part of the hole provides a level of freedom for the explosion energy, and with the hole explosion, the cover between the air column and the drilling debris moves downwards like a piston and increases the pressure at the end of the hole. The generated pressure wave creates horizontal cracks at the end of the pits.

In the next step, the compression wave caused by the explosion is reflected by the created cracks and turns into a tensile wave. Therefore, the rock mass at the end of the hole is crushed due to tensile stress.

In conventional explosions, the pressure of the hole is released from the top of the hole and from the mud laying area, which increases the potential of rock throwing and air vibration, while in the air blast, the gas pressure moves downwards by creating a crack in the lower part of the hole, and as a result In addition to reducing special drilling (elimination of extra drilling) and special expenses, it brings good performance in terms of digging the bottom of the pit and reducing stone throwing.

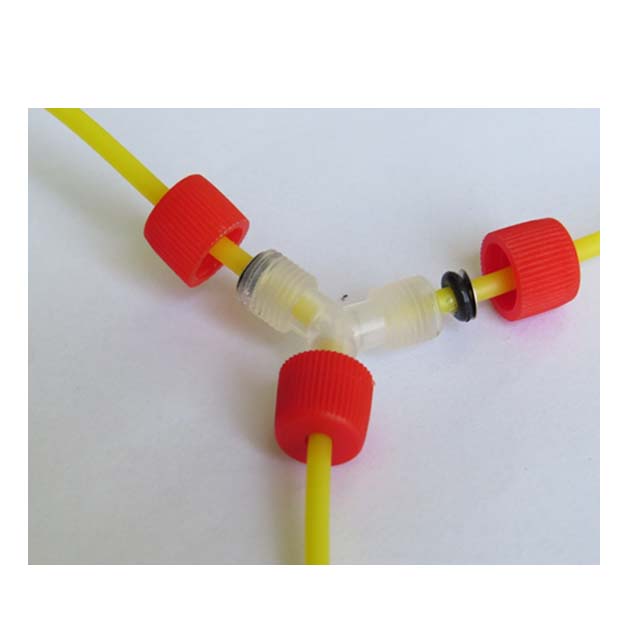

The most important thing in the implementation of this method is to design and manufacture a plug (blocking piece) suitable for blocking the bottom of the pit, which is easy to use and can block the bottom of the pit well with the desired length, and has a reasonable price. This blocking part is made based on the diameter of the hole.

The following are the advantages of this method:

Reduce or eliminate over-drilling

Reducing the cost of raw materials up to 25%

Reduce ground vibration up to 33%

Better stone crushing up to 25%