In blasting with the Nannel system, a connector is generally used to transmit the wave to the blast pits. In order to save money, the wave transmitter has been designed in the form of a three-way, which can be a good substitute for the connector in the Nannel system. In large mines, to create pre-split in order to maintain the mine wall, the use of connector creates a limitation, which the designed three-way solves this limitation. This wave transmission tee is designed in a 120-degree shape so that it can be used in any direction, thus eliminating the possibility of user error. The unique feature of this module is the absence of explosives and it works based on wave splitting. In this method, an in-hole millisecond delay device is used to create the required regular delay. In this patented invention, in addition to about 25% economic savings, all blasting models with Nanel system can be implemented without any restrictions.

Introducing the 120-degree tee:

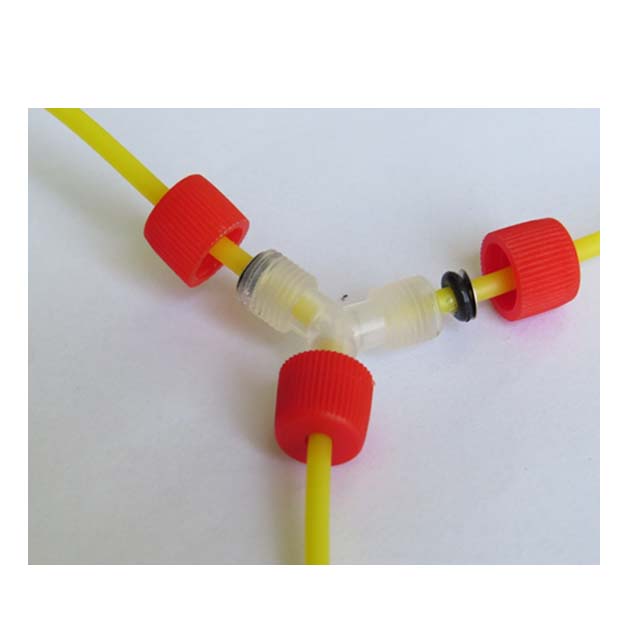

The designed 120-degree tee is a plastic piece that consists of the following four main components (Figure 1):

Main body: made of transparent plastic material

Sealing o-ring: to seal the tube and prevent moisture and water from entering the shock tube

Metal barb: This barb is one-sided, which prevents it from coming out after placing the tube inside the tube.

Cap: for storing spurs and O-rings